Sappi Ngodwana

Desuperheater replacement completed 3 months early

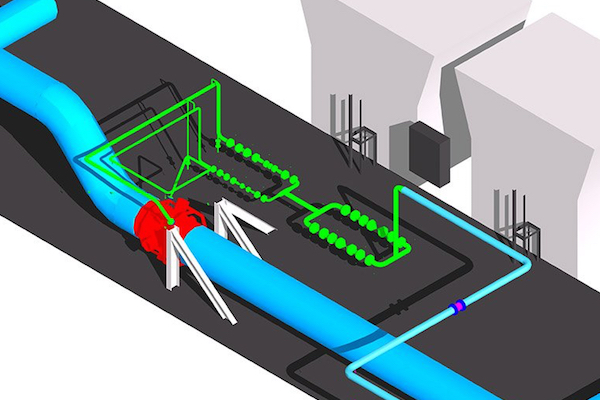

The project required the replacement of an existing 1 100 kPa desuperheater in the steam plant at Sappi Ngodwana, a vital component in the production capacity of the plant as the majority of the mill processes requiring steam cannot operate if the desuperheater system is faulty or shut down. The desuperheater is a system that is used to reduce the temperature of superheated steam by injecting water into it. The water injection is controlled to reduce the steam temperature within close proximity of the saturation temperature of the steam. The two main reasons for lowering the steam temperatures are: (1) to permit operation of downstream process equipment that is designed for lower temperatures, and (2) to maintain a constant temperature for processes that require precise temperature control.

Etienne Wannenburg - Project and System Engineering Manager, explains that when Babcock submitted their proposal the current system was unreliable and not operating as required and that two previous attempts by other organisations to replace the desuperheater were unsuccessful.

“The client required a reliable, high performing system that included an accurate steam temperature control within a 10˚C range with a high turndown and quick response time. Furthermore, it could only allow for maintenance once a year, and we had the added challenge of completing the installation within 11 days,” says Wannenburg.

Despite the short time frame to commission the project, our team responded swiftly to the brief and delivered an engineered solution not only within the specified time constraints, but which also exceeded the client’s expectations. “During our first proposal we put forward a period of eight months to design and supply the equipment. A delay in the placement of the order constricted our time frame; nevertheless, we were able to reduce the engineering and supply duration to five months through resource management, engaging with our suppliers and working through the year-end holiday period,” explains Wannenburg.

Factors attributing to the rapid turn-around time

- The design of the system – aided by Babcock’s in-house 3D scanning and modelling capacity to deliver accurate results

- Ensuring that all the interfacing systems were properly defined and investigated during the design phase

- Efficient interaction between Babcock and their equipment suppliers to ensure correct equipment selection and reduce the delivery period

- Effective design plans allowing for proficient and swift installation

More than a year later, the desuperheater system continues to operate without any failures and we continue to assist Sappi Ngodwana with general maintenance of the annual boiler shutdown.