When Grootvlei Power Station was returned to service, Babcock International Group was awarded a contract to supply burners for the 5 decommissioned MWe boilers units. Low NOx burners revive plant

Low NOx burners revive plant

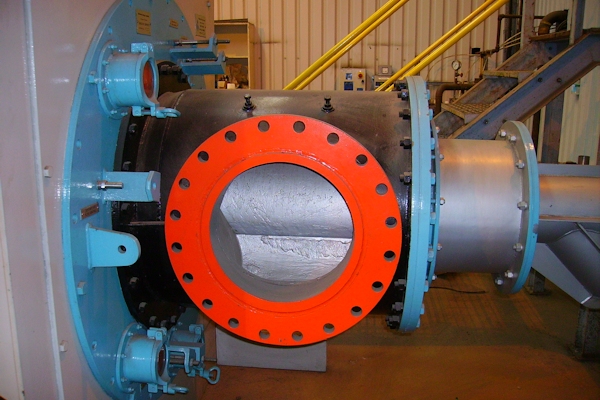

Doosan Babcock's Low NOx Mark 3 burners were installed in a landmark deal, with 120 Mark 3, Low NOx Axial Swirl Burners (LNASB’s) installed on 5 of the 200 MWe boilers. This was the first contract for Low NOx burners to be fitted to any utility boiler in South Africa, this being awarded by ESKOM to Babcock International Group, a longstanding partner and licensee of Doosan Babcock for boiler and combustion technology.

Whilst the burner refit program was driven by a lower specified coal quality, the application of Doosan Babcock's LNASB technology addressed ESKOM's commitment to emission reductions. Supplementary benefits included better control and a higher turndown capability, whilst the design was such that maintenance would be significantly reduced.

With the installation of the burners, the plant was brought back online with increased flexibility, control and reduced emission, whilst maintenance time and cost can be addressed in a more effective way to reduce both. This retrofit project demonstrates the viability of updating older plant to meet the more stringent standards required of modern practice and regulation

As licensor of the technology, Doosan Babcock performed the engineering and design of the installation in Crawley and Renfrew in the UK. The burner's components were manufactured and assembled in South Africa together with the specialist casting in-situ of the wear resistant internal linings.

Interesting fact:

Doosan Babcock was the original supplier of the boilers at Grootvlei in the 60's and 70's. Of the 9GWe of Doosan Babcock and Babcock reference plant installed in South Africa, the 2 x 3,600MWe ‘six-pack’ stations at Lethabo and Matla form a substantial portion of the backbone of South Africa's electricity-generation capacity.