Babcock is capable of conducting dynamic stress analyses on boiler steam piping systems. It was in response to an over-pressurization incident that damaged a 600MW power plant, that these analyses were put into practice.  Dynamic stress analysis of steam piping system

Dynamic stress analysis of steam piping system

It was imperative to ensure adequacy of design for sustainable operation and maintenance, given the high costs of replacing the steam piping systems. This analysis was primarily concerned with determining how dynamic events would affect the integrity of the piping system and determining the supporting mechanisms to ensure code compliance.

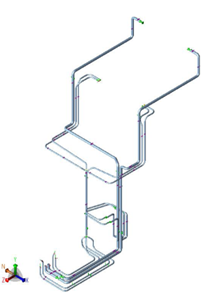

Figure 1: Isometric View of The Main steam, Cold Reheat and Hp Bypass Piping Systems

All piping systems were modelled using a real-time thermo-fluid hydraulic network solver called Flownex. As part of the process engineering process, static as well as dynamic analyses were performed.

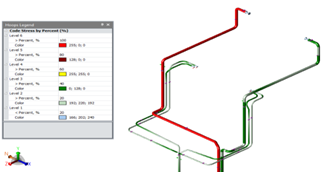

Figure 2: Overstress in piping leg (left) versus systems within allowable stress range (right).

For the calculation and evaluation of stresses, thermal displacements, and reaction forces, EN 13480-3 was adhered to. A code-compliant design was achieved by implementing dynamic restraints at carefully considered locations in order to reduce uncontrolled displacements and stresses.