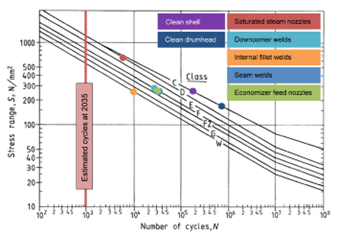

Major sources of stress cycling considered in the fatigue analysis, were pressure cycles, temperature transients and nozzle loads caused by thermal expansion on a system scale. It was done in the context of a life extension study to determine whether the boiler could be safely used until 2035. Fatigue assessment of a boiler steam drum

Fatigue assessment of a boiler steam drum

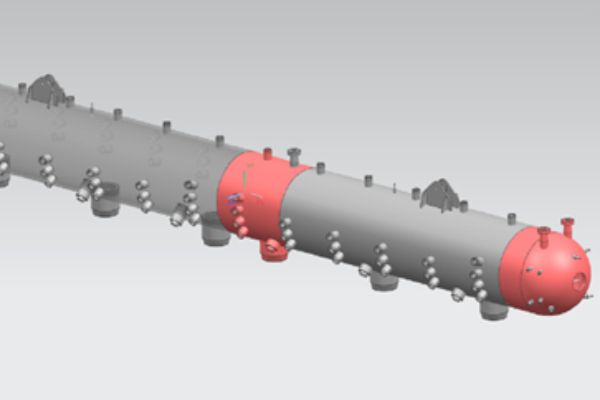

Figure 1: Sections of the steam drum chosen for Finite Element Analysis (shown highlighted).

The approach was to evaluate the importance of different effects in a few stages of analysis and then to conduct a final analysis that only incorporated the necessary detail. The stages of analysis included:

- Pressure and thermal cycling of an idealised steam drum with no stress raisers.

- Thermal analysis.

- Detailed fatigue analysis.

Figure 2: Summary of Results on PD5500 S-N Curves

The work aimed to address all factors that could affect the fatigue life of the steam drum significantly and hence cause premature failure (before 2035). Effort was directed at major drum features of which failure would lead to high-risk repairs.