Selecting the right welding power source can be simple yet profitable if you carefully consider the application as well as the advantages of each welding process. There are many types of welding processes, from simple oxy-fuel to high-tech laser beam. How to choose the right welding machine

How to choose the right welding machine

The most common welding processes used for fabricating metals are:

- Gas metal arc welding (MIG)

- Flux cored welding (FCAW)

- Gas tungsten arc welding (TIG)

- Shielded metal arc welding (stick electrode)

- Sub-arc welding

To evaluate the welding process most appropriate for the job at hand, the following factors would typically be considered:

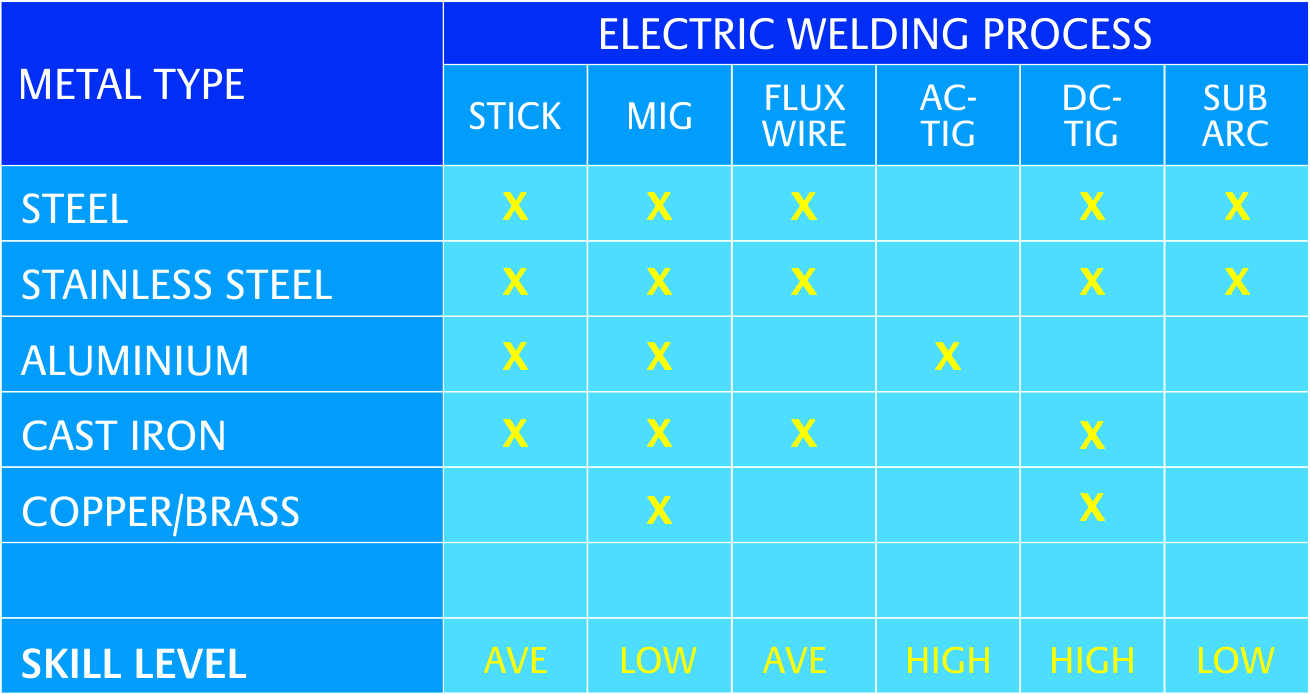

- Type of material being welded (see table below)

- Thickness of the material

- The welding position

- Type of welding power source and the amount of current available

- Time requirements

- Working conditions

Babcock’s welding specialists can provide expert advice on the variables involved and which process and equipment will be best suited to your application. We supply a wide range of welding supplies, welding machines, consumables, robotic welding solutions and offer superior service in the maintenance and repair of all makes of welding machines - electrical or engine driven.