Babcock has implemented various welding management software packages to digitize and control welding data and improve welding performance. Babcock elected to transfer to a new welding system which is developed and maintained by TWI. Welding Data Management Systems

Welding Data Management Systems

This welding system is an integrated system which addresses the following aspects of welding documentation/information and reporting:

- Welding Procedure Qualifications

- Welder Qualification Records

- Capturing of Welding Activities

The TWI system is pre-loaded with the relevant codes, standards, material classifications, and qualification ranges are auto generated. The information is housed in a central data base which is accessible to all Babcock sites.

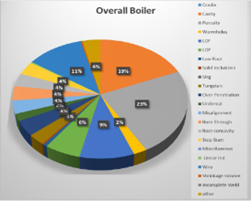

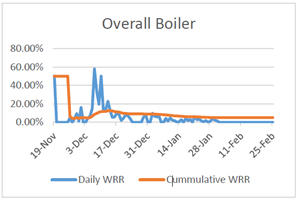

The system can be used to manage welder qualification records, monitoring of welding scope progress, welder performance monitoring, weld repair rate assessment (including trend monitoring of weld repair rates, productivity, and defect classification), and to produce data books.

Figure 1: Examples of weld repair rate and defect classification analyses at a client’s plant.

With the implementation of Babcock’s new welding system, it will be able to record, control and improve all aspects of the welding process. Babcock is confident that this new system will enhance our current welding services.