As part of a responsible maintenance philosophy, a client with six 665 MWe coal fired boilers, conducted extensive metallurgical surveys on its dated DIN mainsteam piping system which had only run approximately for half of its designed life at this point.

The plant

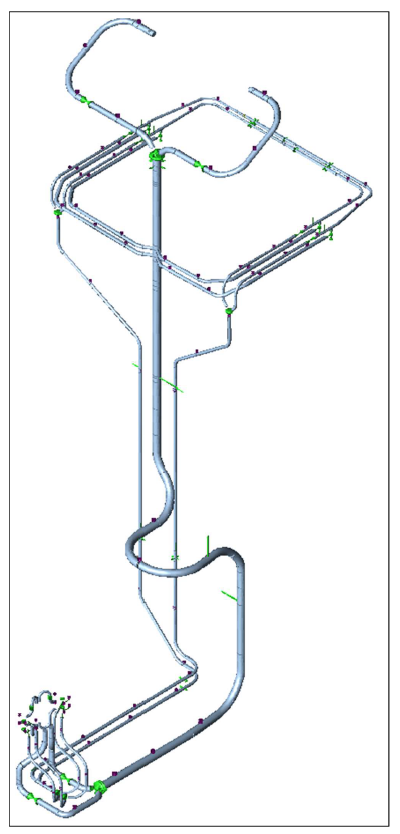

The mainsteam piping followed a 4-2-4 configuration, where four boiler lines feed two vertical common lines and then spilt into four lines feeding the turbine.

The challenge

The challenge was to replace the pipework with the best possible configuration. Therefore the design had to be viewed in different perspectives, taking the following into consideration:

- Best material for the service

- Loads on existing structures and pipe hangers

- Existing piping and structures around the header that could obstruct the thermal movement of the header

- Constructability

With the material selected for the replacement having a higher yield strength and better creep resistance, the replacement piping would be considerably lighter than the original pipework. This critical clue would then lead to the entire supporting system being replaced.

Due to the client’s restrictive outage duration, Babcock was prompted to solve the problem through using technology in groundbreaking ways. Streamlining both the design process and construction methods through in-depth analysis and planning.

The conclusion

By sourcing out all the aspects of the project, the client empowered Babcock to deliver an outstanding service. From developing a detailed design to supply of all the appropriate material for piping and finally implementation of the design on site, all these factors contributed to a successful outcome.

Download the detailed white paper

Figure 1: Model of the mainsteam, HP bypass and hot reheat piping layout.